Search This Supplers Products:Dry CoolersHeating & Cooling CoilsEvaporator CoilsCondenser Coils

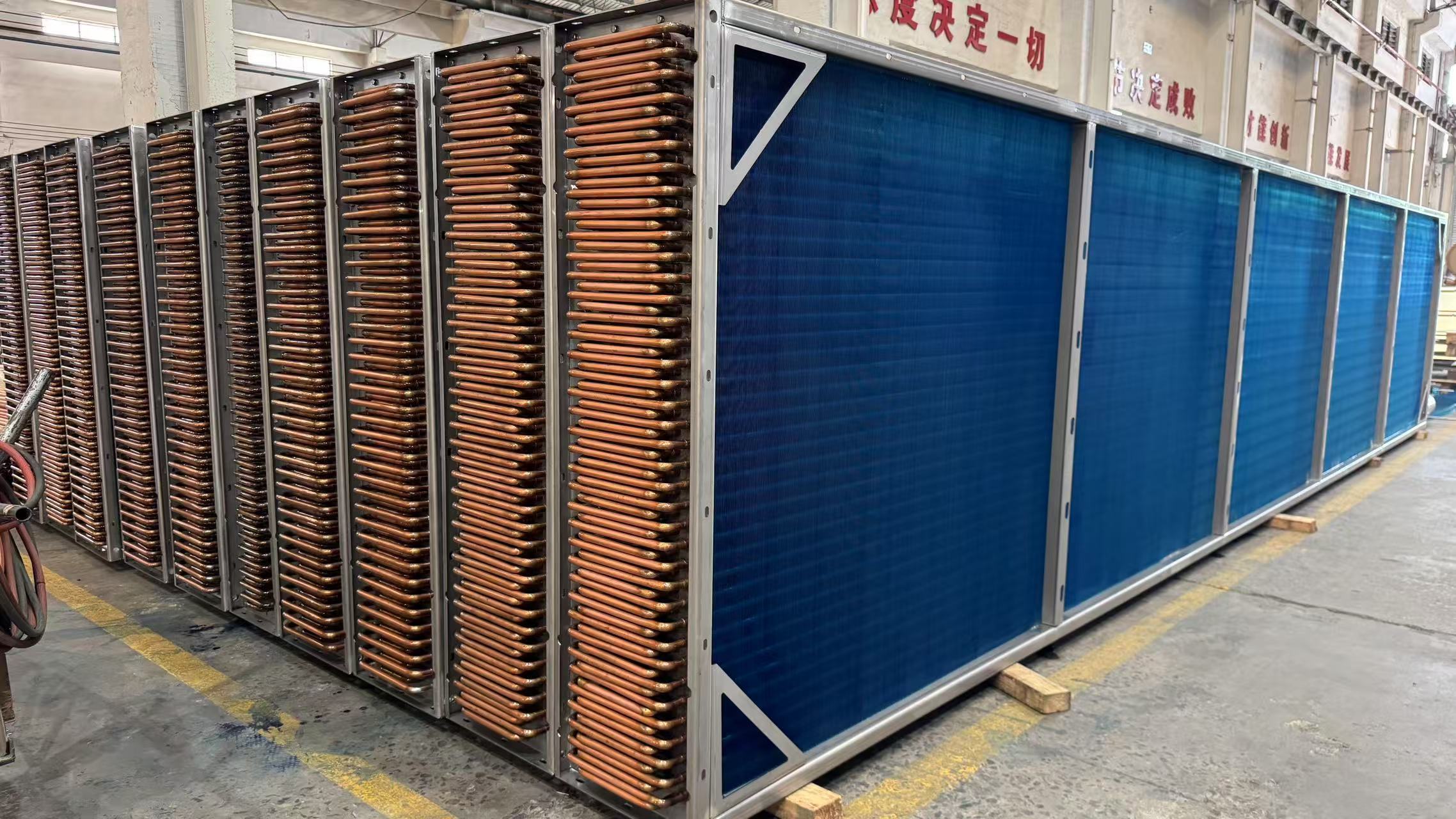

Copper Tube + Aluminum Fin Surface Cooler for Steel Industry

- group name

- Heating & Cooling Coils

- Min Order

- 1 piece

- brand name

- Boyi Heat Exchanger Custom Manufacturing

- model

- BY-BLQ

- Nearest port for product export

- Shenzhen, Guangzhou, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Thu, 12 Feb 2026 04:10:41 GMT

Paramtents

Core Component Finned tube heat exchangers

Tube Diameter 7mm, 9.52mm, 12.7mm, 15.88mm

Casing Material Galvanized Steel, Aluminium, Stainless Steel

Tube Material copper, stainless steel

Fin Material aluminum, copper, stainless steel

Packging & Delivery

-

Min Order1 piece

Briefing

Introducing our Surface Cooler, a cutting-edge industrial cooling system designed specifically for Steel industry.

Detailed

Copper Tube + Aluminum Fin Surface Cooler for Steel Industry

The blast furnace dehumidification technology is an important energy-saving and consumption-reducing method in blast furnace ironmaking. It primarily stabilizes furnace conditions, reduces the coke ratio, and increases pulverized coal injection by lowering the humidity in the blast air, thereby enhancing production efficiency and economic benefits.

The role of blast furnace dehumidification

1. Reduce the coke ratio: For every 1g/m³ reduction in moisture content in the blast, the coke ratio can be lowered by 0.8~1.0kg/t of iron, as the moisture consumes heat by reacting with coke at high temperatures.

2. Increase the pulverized coal injection ratio: Reducing humidity can increase the theoretical combustion temperature at the tuyere. For every 1g/m³ decrease in moisture, an additional 1.5~2.0kg of coal per ton of iron can be injected.

3. Blast furnace stability: Fluctuations in atmospheric humidity can affect the blast furnace heat balance. After dehumidification, the blast humidity stabilizes, reducing furnace temperature fluctuations and improving production stability.

4. Increase the air volume: After dehumidification, the air density increases, which is equivalent to approximately a 9% increase in air volume, thereby enhancing the blast furnace's production capacity.

Conclusion

The blast furnace dehumidification technology is a key measure for energy conservation and consumption reduction in the steel industry. Machine-side dehumidification, with its low energy consumption and high adaptability, has become the future development direction. As domestically produced equipment matures, this technology will be more widely adopted in steel enterprises.

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us