Search This Supplers Products:Dry CoolersHeating & Cooling CoilsEvaporator CoilsCondenser Coils

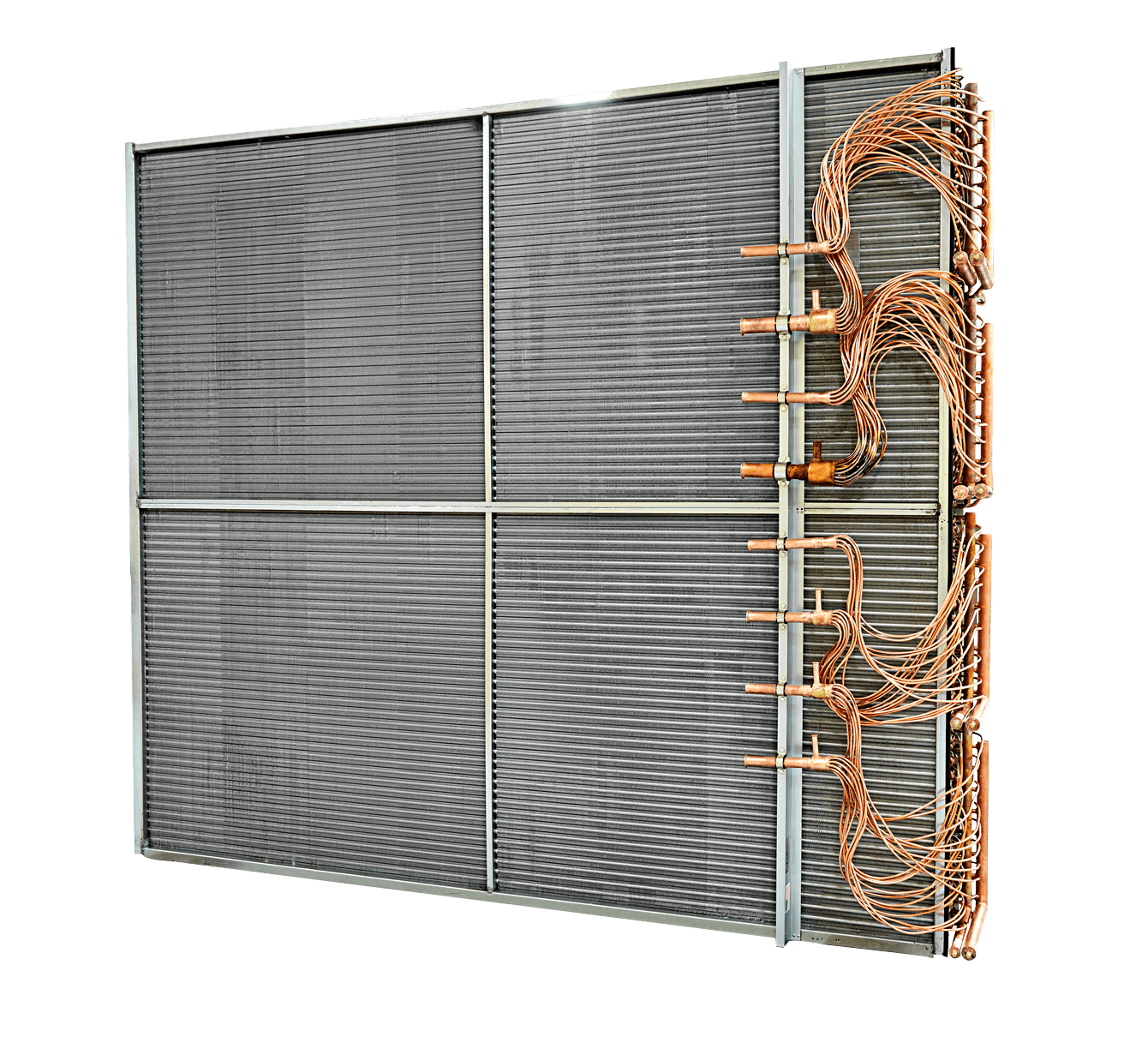

Energy-Saving Copper Tube Aluminum Fin Water to Air Evaporator

- group name

- Evaporator Coils

- Min Order

- 1 piece

- brand name

- Boyi Heat Exchanger Custom Manufacturing

- model

- BY-ZFQ

- Nearest port for product export

- Shenzhen, Guangzhou, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Sat, 06 Dec 2025 06:04:45 GMT

Paramtents

Core Component Finned Tube Heat Exchanger

Tube Diameter 7mm, 9.52mm, 12.7mm, 15.88mm

Casing Material Galvanized Steel, Aluminium, Stainless Steel

Tube Material Copper, Stainless Steel

Fin Material Aluminum, Copper, Stainless Steel

Packging & Delivery

-

Min Order1 piece

Briefing

Evaporator coils are part of a refrigeration or air conditioning system. They're where the refrigerant evaporates, absorbing heat from the surrounding air.

Detailed

Energy-Saving Copper Tube Aluminum Fin Water to Air Evaporator

Evaporator coils are used to absorb heat in air-conditioning or refrigeration systems. They facilitate a crucial step in the refrigeration cycle by allowing low-temperature, low-pressure liquid refrigerants to evaporate into gas, thereby absorbing heat from the surrounding environment. Evaporator coils are one of the four main components in the refrigeration or air-conditioning cycle. Whether in commercial central air-conditioning systems or precise industrial cooling equipment, evaporator coils provide efficient cooling. Especially in environments requiring strict control of humidity and air quality, the role of evaporator coils is particularly prominent.

How They Work

1. Refrigerant Flow: Low-pressure liquid refrigerant enters the coil via an expansion valve, which regulates the flow.

2. Heat Absorption: As warm air passes over the coils, the refrigerant absorbs heat, causing it to evaporate into a gas.

3. Cool Air Circulation: The now-cooled air is blown into the living space (in ACs) or cools the refrigerator compartment.

4. Cycle Continuation: The gaseous refrigerant travels to the compressor to restart the cycle.

Construction & Materials

1. Metals Used: Typically copper (for tubing) and aluminum (for fins) due to their excellent thermal conductivity.

2. Design Features: Fins increase surface area for efficient heat exchange. Coil shapes vary (e.g., A-shaped in ACs, flat in fridges).

Types of Evaporator Coils

1. A-Coils: Common in residential ACs, shaped like an "A" for optimal airflow.

2. Slab Coils: Flat designs used in refrigerators and freezers.

3. Multi-Circuit Coils: Found in commercial systems for handling larger loads.

Applications

1. Residential: AC units, refrigerators.

2. Commercial: Walk-in coolers, supermarket display cases.

3. Industrial: Large-scale refrigeration, chemical processing.

4. Heat Pumps: Act as evaporators in cooling mode and reverse to condensers in heating mode.

Maintenance & Common Issues

1. Dirt/Dust Buildup: Reduces efficiency; clean coils annually with a soft brush or coil cleaner.

2. Ice Formation: Caused by low refrigerant, poor airflow, or faulty components. Address promptly to prevent damage.

3. Refrigerant Leaks: Lead to poor cooling; require professional repair.

4. Bent Fins: Restrict airflow; gently straighten with a fin comb.

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us