Search This Supplers Products:Dry CoolersHeating & Cooling CoilsEvaporator CoilsCondenser Coils

Custom Dry Cooler Free Cooling Systems in Liquid-cooled Data Center

- group name

- Dry Coolers

- Min Order

- 1 piece

- brand name

- Boyi Heat Exchanger Custom Manufacturing

- model

- BY-V-GLQ

- Nearest port for product export

- Shenzhen, Guangzhou, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Wed, 21 Jan 2026 15:41:50 GMT

Paramtents

Core Component Finned Tube Heat Exchangers

Tube Diameter 7mm, 9.52mm, 12.7mm, 15.88mm

Casing Material Galvanized Steel, Aluminium, Stainless Steel

Tube Material Copper, Stainless Steel

Fin Material Aluminum, Copper, Stainless Steel

Packging & Delivery

- 1090cm x256cm x280cm

-

Min Order1 piece

Briefing

The core advantages and application potential of dry cooler free cooling systems in liquid-cooled data centers.

Detailed

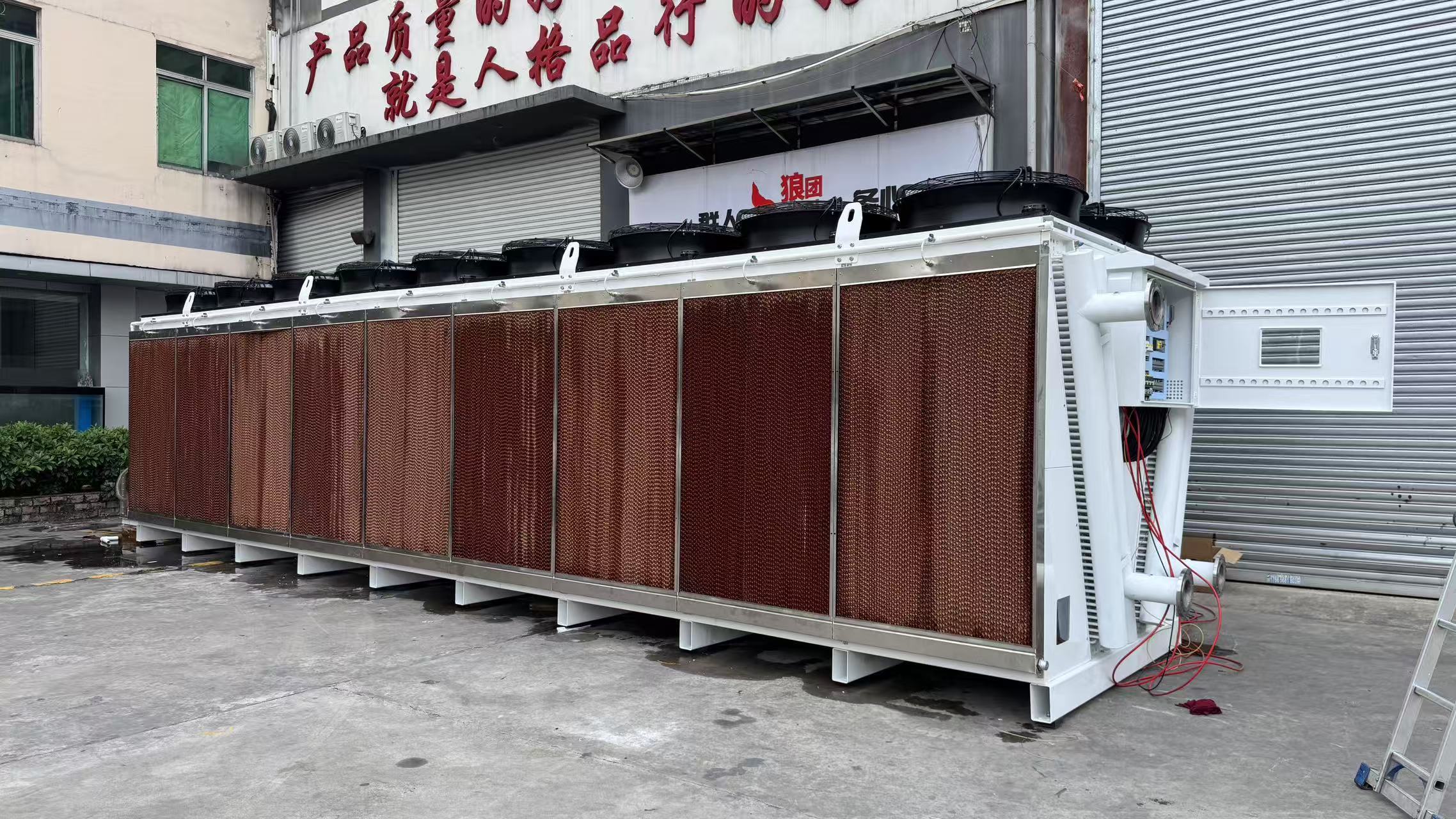

Custom Dry Cooler Free Cooling Systems in Liquid-cooled Data Center

1. V-Type design for easy installation and space-saving.

2. Efficient heat dissipation to prevent equipment overheating.

3. Specifically designed for industrial cooling systems in data centers.

4. Reliable and durable construction for long-lasting performance.

Background

Against the backdrop of increasingly severe energy consumption challenges in data centers, liquid cooling technology has become an industry focal point due to its high heat dissipation efficiency. Meanwhile, natural cooling systems incorporating dry coolers offer a sustainable new pathway for liquid-cooled data centers, leveraging their unique advantages in water conservation, energy efficiency, and cost-effectiveness. This article will analyze the core strengths of dry coolers, their synergistic effects with liquid cooling systems, performance enhancement strategies during high-temperature seasons, and applicable scenarios, highlighting their critical role in the green transformation of data centers.

The core advantages of dry cooler: From water conservation to cost reduction

1. Zero Water Consumption and Ultimate Water Saving (WUE≈0):

The dry cooler operates on the principle of sensible heat exchange—the coolant circulates within sealed fin tubes, with heat dissipated solely through air convection, eliminating the need for water evaporation or consumption. Compared to traditional cooling towers (with a WUE as high as 1.5–2 L/kWh), its water usage efficiency (WUE) approaches zero. For example, a 10MW data center adopting dry coolers can save up to 500,000 tons of water annually, equivalent to the yearly water consumption of 5,000 households.

2. Low Investment and Operational Costs:

2.1 Lower Initial Costs: Dry coolers have a simple structure with no complex components such as water pumps or cooling towers, reducing initial investment by 30%-40% compared to wet cooling systems.

2.2 Reduced Maintenance Expenses: Eliminating the need for water treatment equipment, chemical additives, or regular water replenishment cuts operational costs by over 50%, while also avoiding issues like scaling and corrosion.

3. Highly compatible with various environments:

3.1 Emission-free: No risk of drift water, white mist, or chemical leakage, making it suitable for sensitive areas such as cities and ecological reserves.

3.2 Excellent weather resistance: Featuring anti-corrosion coating and modular design, it ensures stable operation within a broad temperature range of -30℃ to 50℃.

The synergistic mechanism between liquid cooling and dry cooler

1. High-temperature liquid cooling design extends the natural cooling range:

The liquid cooling system allows the coolant to operate at higher temperatures (e.g., 35-45°C), whereas traditional air cooling systems require the air to be cooled below 25°C. This "high-temperature liquid supply" feature significantly increases the applicable ambient temperature threshold of dry coolers.

Traditional cooling system: Requires air temperature ≤15°C to initiate natural cooling.

Liquid cooling + dry cooler: Effective heat dissipation can be achieved when air temperature is ≤40℃, extending natural cooling duration by 3-5 times.

2. High-density heat dissipation capability meets liquid cooling requirements:

The liquid cooling system can achieve a single cabinet power of over 50kW (typically <30kW for air cooling), and the dry cooler handles high loads through the following methods:

2.1 Large temperature difference heat exchange: The supply and return water temperature difference in liquid cooling systems can reach 10-15°C (compared to only 5°C for air cooling), improving the heat exchange efficiency of dry coolers by 20%-30%.

2.2 Modular expansion: On-demand addition of dry cooler units to flexibly match data center capacity expansion requirements.

High-temperature seasonal performance enhancement strategy

Although dry coolers are sensitive to high-temperature environments, the following hybrid technologies can overcome climatic limitations:

1. Water spray auxiliary cooling:

Principle: Spray atomized water at the air inlet of the dry cooler to utilize evaporative cooling and reduce the air temperature. Experiments have shown that spray cooling can lower the inlet air temperature by 3-8°C.

The water balance: the spray system is only activated during high wet-bulb temperature periods, while the overall WUE can still be controlled at 0.1–0.3 L/kWh, far lower than traditional water-cooling systems.

2. Wet Curtain Evaporative Cooling System:

Structure: Install a honeycomb wet curtain in the air passage to evenly moisten the surface through capillary action.

Advantages: Saves 50% more water than spray systems and prevents droplets from entering the dry cooler, avoiding scaling.

3. Phase change cold storage technology:

Nighttime cold storage: Utilizing the excess heat dissipation of dry coolers during low-temperature periods to store cooling capacity in phase change materials (such as paraffin wax or salt hydrates).

Daytime cooling release: Releasing stored cooling capacity during high-temperature periods to compensate for the reduced efficiency of dry coolers.

Ideal application scenarios and economic benefits

1. Climate-driven efficient scenarios:

Cold and dry regions (e.g., Northern Europe, Northwest China): The annual average temperature is below 15°C, allowing year-round natural cooling to be achieved directly through dry coolers.

Regions with large diurnal temperature variations (e.g., deserts, plateaus): Storing cold energy during low nighttime temperatures and releasing it during the day. For example, a data center in Inner Mongolia reduced its PUE to 1.08 using phase-change cold storage.

2. Economic benefit model:

Return on Investment: Taking a 10MW data center as an example, the initial investment for a dry cooler system is approximately 8 million yuan, saving 3 million yuan compared to traditional water cooling. It conserves 500,000 tons of water annually (saving 1.5 million yuan in water costs) and reduces electricity consumption by 5 million kWh (saving 2.5 million yuan in electricity costs), with a payback period of just 2-3 years.

Carbon Emission Reduction: After phasing out the compressors, the annual carbon dioxide emissions are reduced by 4,000 tons, equivalent to planting 200,000 trees.

Practical Case: Zhangjiakou Zero Water Consumption Data Center

Zhangjiakou has built Asia's largest liquid-cooled + dry cooler data center cluster, leveraging its cold winters and cool summers.

Liquid cooling system: 40°C supply liquid temperature, direct chip-level heat dissipation.

Dry cooler configuration: 12 modular dry coolers with a total cooling capacity of 15 MW, integrated with wet pad systems for extreme summer weather conditions.

Operating metrics: PUE = 1.07, WUE = 0, with annual water savings equivalent to filling 200 standard swimming pools.

Future Prospects: Technological Optimization and Global Expansion

1. Direction of technological innovation:

Intelligent Control: AI algorithms optimize fan speed, spray frequency, and cold storage strategies in real-time, improving energy efficiency by 10%-15%.

Application of new materials: Graphene-coated fins can increase heat exchange efficiency by 25%, while nano waterproofing technology reduces the impact of dust accumulation.

2. Climate-adaptive site selection:

Arctic Data Center: Utilizing -30°C extreme cold air, dry coolers achieve natural convection heat dissipation without the need for fans.

Underwater Data Center: Microsoft's Project Natick Confirms Feasibility of Seawater Cooling, Dry Coolers Can Replace High-Energy Seawater Pumps.

Conclusion

The integration of liquid-cooled data centers and dry cooler-based free cooling systems not only addresses the heat dissipation challenges of high-density computing but also redefines the sustainability standards of data centers with their "zero water consumption and near-zero carbon emissions" features. Although their performance is constrained by climatic conditions, advancements such as high-temperature liquid cooling designs, hybrid cooling strategies, and intelligent control technologies have elevated dry coolers from regional solutions to a core pillar of global data center green transformation. Driven by the "dual carbon" goals, this technological pathway will accelerate the evolution of data centers from "energy black holes" to "environmental partners."

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us